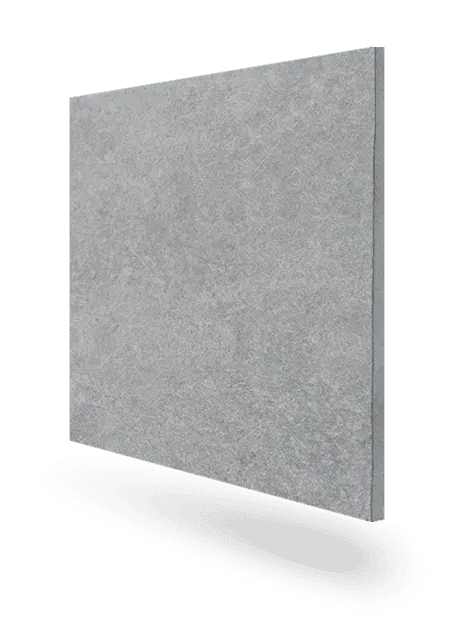

Vboard – Fiber Cement Boards

Fiber cement boards have recently gained a lot of popularity on a global scale. With many of them choosing to substitute fiber cement board solutions for conventional building materials, its great range of advantages has attracted great support and praise from clients and architects all around. Some of the most iconic structures of our day have been built using VBoards since they are safer, save time and money, and are more aesthetically pleasing. The Hatschek process and High Pressure Steam Curing (HPSC) technology are utilized in the production of VBoards, which are fiber cement boards that are also autoclaved and do not contain asbestos products. Non-asbestos cellulose fibers, regular portland cement, fine silica, quartz, fly ash, and mineral additives are the components that make up the composite matrix of VBoards. In order to fulfill the mandates of contemporary architectural applications, VBoards are made in accordance with the standards of IS 14862-2000 and come with surface treatments that have a textured appearance. With the introduction of VBoards, we've taken the phenomenon of fiber cement board for interiors and exteriors to a whole new level. To make room for a living that is both environmentally friendly and resistant to the elements, here is a game-changer that will provide the building sector with the much-needed facelift it urgently needs.